Automatic 3 In1 Barreled Mineral Pure Water Filling Machine

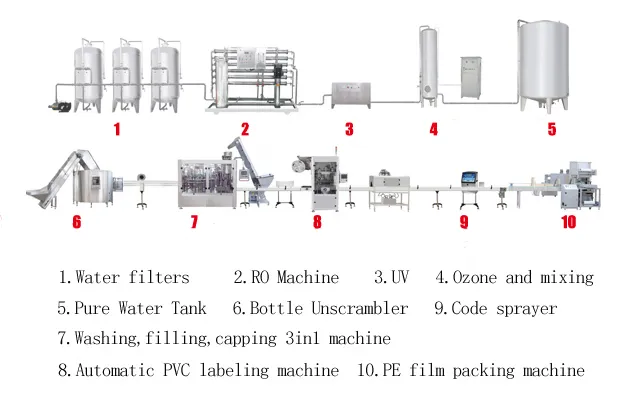

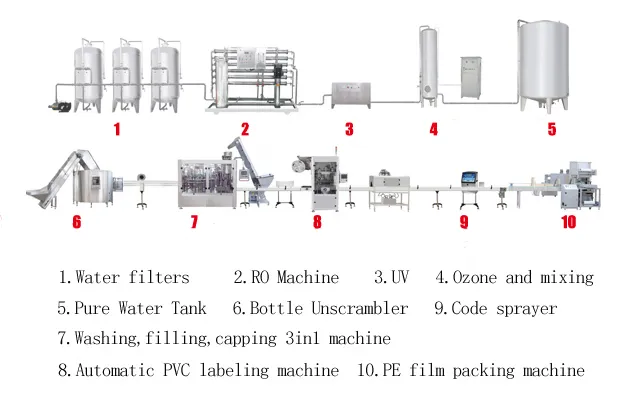

Automatic 3 In1 Barreled Mineral Pure Water FillingMachineWater Filling Machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral......

Send Inquiry

Product Description

Automatic 3 In1 Barreled Mineral Pure Water FillingMachine

Water Filling Machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

General Descriptions

This machine works harmoniously with air-conveyor belt; it holds the bottles by the neck when transporting

This machine is used to fill water into pet bottle and with screw caps capping function.

Integrated three function: 1. Rinse the empty pet bottle, 2. filling the rinsed bottles, 3. capping the filled bottles

Rinser Station

Neck Control with plastic snap on the gripper.

Water distributor combined with Food Grade Rubber plate & SUS304 cover.

SUS304 water collecting tray

Spraying inject design, can completely washing the bottles.

Washed water recycling system, for water saving !! (Washed bottle---drip in water tank--water pump---raw water tank)

Filler Station

The entire filler is isobar filling system.

High accurate SUS304L construction filling nozzle, make sure high accurate filling level

SUS304L liquid bowl, & pipeline system.

No bottles, no filling

Annulus Liquid bowl, with automatic water level controller

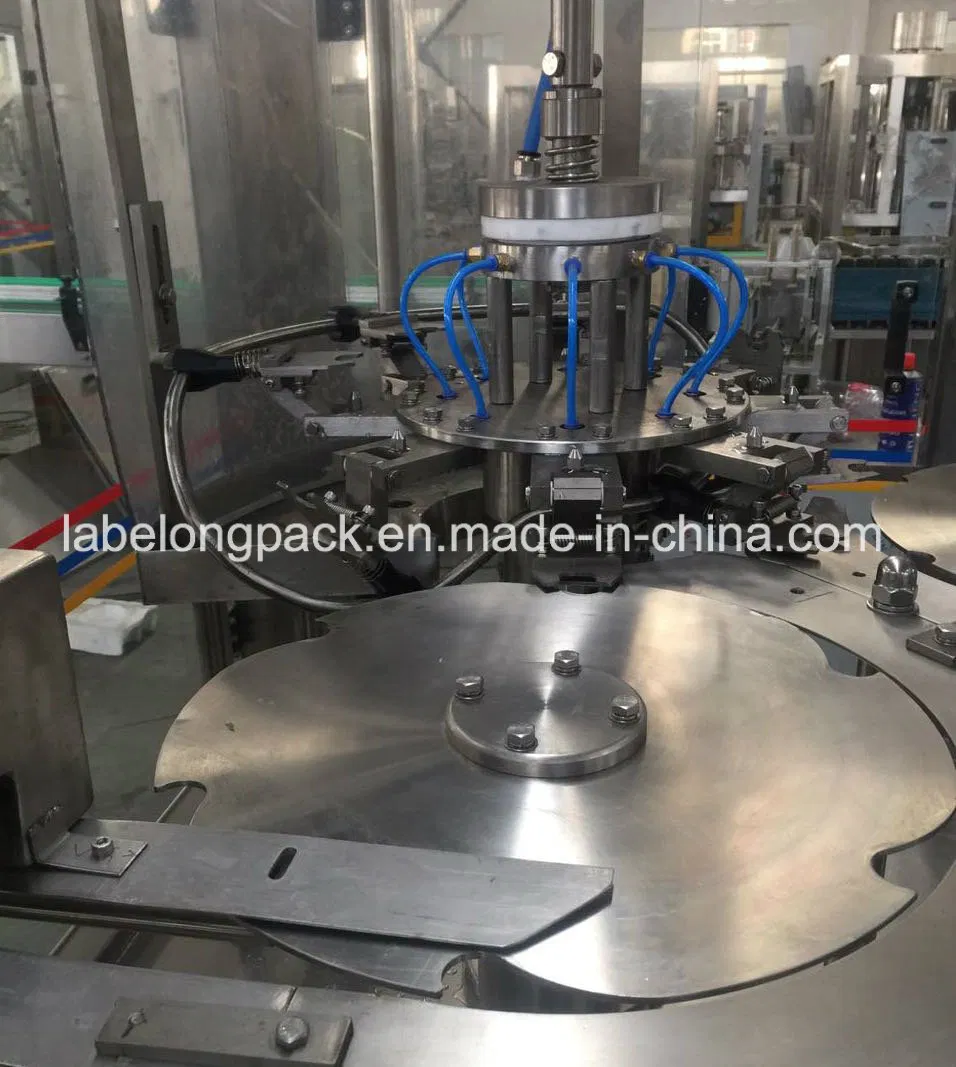

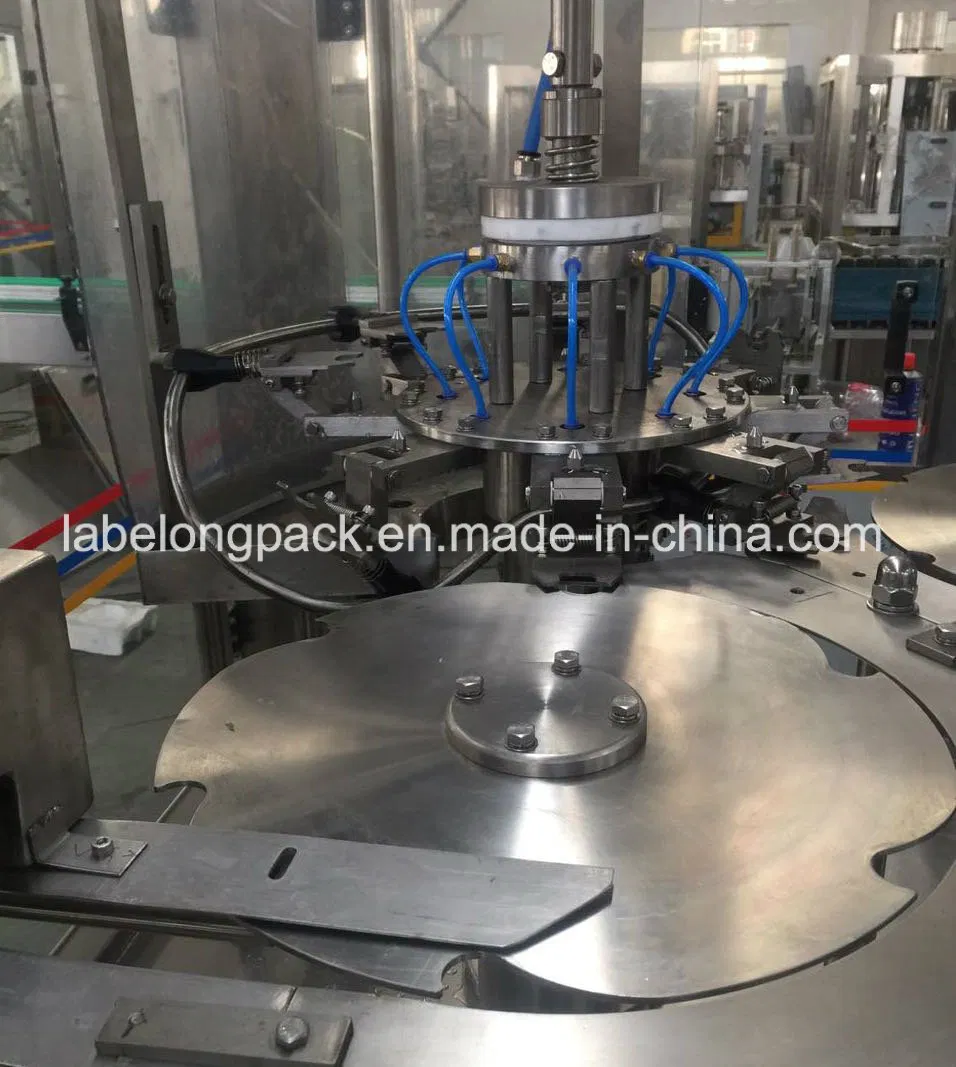

Capper station

Place & capping system. Automatic caps arranging, feeding.

Electromagnetic capping heads, with burden discharge function,

All 304stainless steel construction

No bottle no caps delivery.

Automatic stop when lack of bottle.

Technical Parameter

Configuration List:

Factory

Labelong focus on filling, packing & water treatment field, our factory takes up 60000 square meters ,more than 30 Professinal Tehchnicians and workers which is one of the professional & reliable Chinese manufacturers & provider for liquid & semi-liquid filling & packaging machinery, blow molding machines and water treatment systems with reliable quality & pretty good after sale service with CE certification & ISO9000:2001 certification.

Our machine list

Work shop

Contact me for more information and video

Water Filling Machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

General Descriptions

This machine works harmoniously with air-conveyor belt; it holds the bottles by the neck when transporting

This machine is used to fill water into pet bottle and with screw caps capping function.

Integrated three function: 1. Rinse the empty pet bottle, 2. filling the rinsed bottles, 3. capping the filled bottles

Rinser Station

Neck Control with plastic snap on the gripper.

Water distributor combined with Food Grade Rubber plate & SUS304 cover.

SUS304 water collecting tray

Spraying inject design, can completely washing the bottles.

Washed water recycling system, for water saving !! (Washed bottle---drip in water tank--water pump---raw water tank)

Filler Station

The entire filler is isobar filling system.

High accurate SUS304L construction filling nozzle, make sure high accurate filling level

SUS304L liquid bowl, & pipeline system.

No bottles, no filling

Annulus Liquid bowl, with automatic water level controller

Capper station

Place & capping system. Automatic caps arranging, feeding.

Electromagnetic capping heads, with burden discharge function,

All 304stainless steel construction

No bottle no caps delivery.

Automatic stop when lack of bottle.

Technical Parameter

| Item | Technical Parameter |

| Production Output | 2500BPH @ 500ml PET bottle |

| Rinsing heads | 8pcs |

| Filling nozzles | 8pcs |

| Capping heads | 3pcs |

| Suitable to PET bottle Size | Diameter Φ50~Φ95mm Highness:160~320mm, Bottle neck: 28mm, Bottle volume from 200 to 2250ml |

| Suitable to Caps | PCO28 |

| Washing Water Required | 2000 liter per hour |

| Washing Pressure Required | 0.2Mpa |

| Washing time | 3 second |

| Drip water time | 3 second |

| Working Power | 380V AC 3-phase |

| Compressed Air Pressure (for caps arranger) | 0.8MPa |

| Compressed Air Consumption (for caps arranger) | 2m3/min |

| Control Panel Power | 24V DC |

| Filling Pressure | gravity |

| Filling temperature | 85 degree |

| Machine Size | 6000x5000x2750mm |

| Gross Weight | 6,000kg approximately |

| Total Power | 1.3KW |

Configuration List:

| Item | Parts Name | Brand from |

| 1 | PLC | Germany |

| 2 | Inverter | |

| 3 | Touch Screen | |

| 4 | Switch | France |

| 5 | Contactor | |

| 6 | Relayer | |

| 7 | Solenoid Valve | Germany |

| 8 | Drive motor | Germany |

| 9 | Reducer | |

| 11 | Main Bearing | Japan |

| 12 | Sensor | Japan |

| 13 | Air component | Germany |

| 14 | Stainless Steel Frame | Korea |

Factory

Labelong focus on filling, packing & water treatment field, our factory takes up 60000 square meters ,more than 30 Professinal Tehchnicians and workers which is one of the professional & reliable Chinese manufacturers & provider for liquid & semi-liquid filling & packaging machinery, blow molding machines and water treatment systems with reliable quality & pretty good after sale service with CE certification & ISO9000:2001 certification.

Our machine list

| No. | Production line category | Capacity |

| 1 | Hot filling production line | 3,000-36,000BPH |

| 2 | Beverage processing System | 1,000 Ltrs/H to 10,000 Ltrs/H |

| 3 | Bottled water production line | 3,000-36,000BPH |

| 4 | 5L Large capacity bottled water production line | 700-5,000b/h |

| 5 | Carbonated drink production line | 3,000-18,000b/h |

| 6 | Pulp juice production line | 5,000-22,000BPH |

| 7 | Oil Filling line | 3,000-10,000BPH |

| 8 | Linear Filling machine | 300-900BPH |

| 9 | Bottlle Unscrambler | Up to 20,000BPH |

| 10 | Barrelled water production line | 300-2000 bucket/H |

| 11 | Water Treatment system | 1,000 Ltrs/H to 10,000 Ltrs/H |

| 12 | OPP Labeling machine | 6,000-24,000BPH |

| 13 | PVC Shrink Sleeve Labeling machine | 6,000-24,000bph |

| 14 | Automatic Blow molding machine | 1,000-7,000BPH |

| 15 | Full-automatic Film Wrapper & Shrinker |

Work shop

Contact me for more information and video

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.