Automatic Juice Beverage Filling Machine Equipment

AS1000 Automatic Filling Fruit Juice Drinking Mineral Water Sachet Liquid Packaging MachineProduct DescriptionThis liquid packing machine is precisely controlled by PLC, it can automatically complete all the production process like bag making, counting, filling, sealing and coding batch number, add......

Send Inquiry

Product Description

AS1000 Automatic Filling Fruit Juice Drinking Mineral Water Sachet Liquid Packaging Machine

Product Description

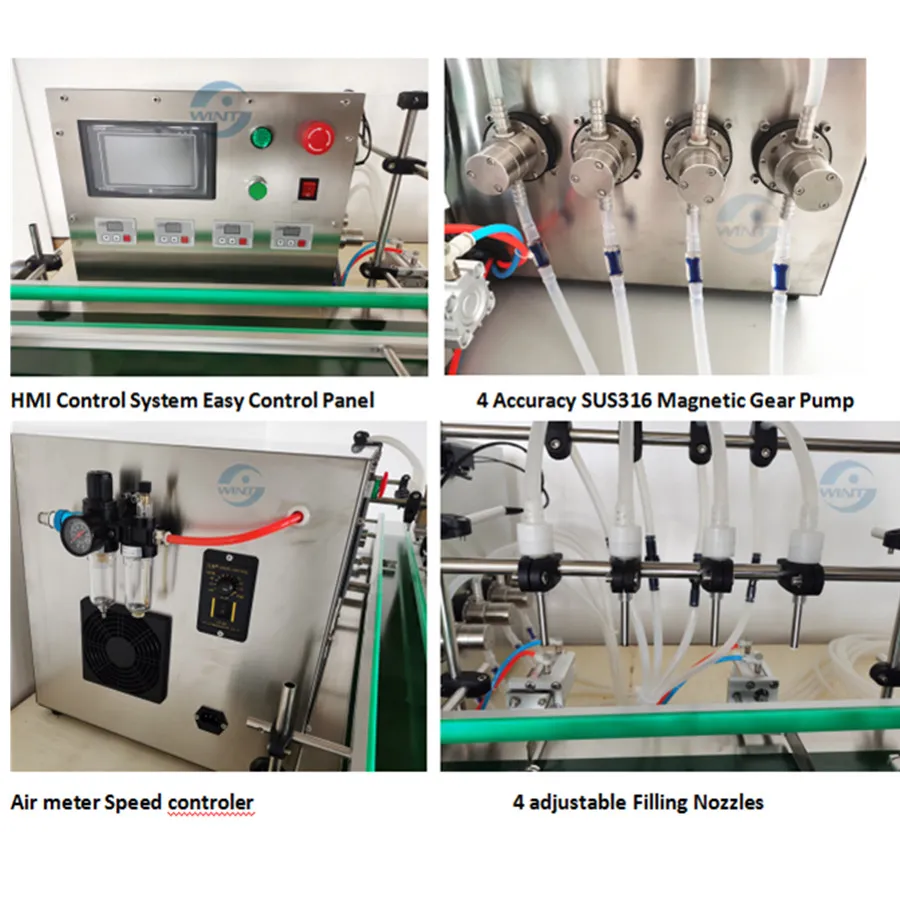

This liquid packing machine is precisely controlled by PLC, it can automatically complete all the production process like bag making, counting, filling, sealing and coding batch number, adding easy to open notch, cutting separated or connected bags. It uses 304SS nozzles and valves and reduces filling error, more suitable for filling different kinds of liquid, such as milk, sauce, soymilk, vinegar, etc. All parts that get contacted with liquid is made of the 304SS, additionally, this machine can add color ribbon coding, dust cover and sterilizing lamp.

Product parameters

| Model | SJ-1000 | SJ-2000 |

| Bag-making length | 50-150mm | 50-250mm |

| Bag-making width | 40-150mm | 40-175mm |

| Packing film width | 100-320mm | 100-380mm |

| Packing capacity | 100-500ml | 200-1000ml |

| Packing speed | 2000-2200bags/hour | 1100-1300bags/hour |

| Power | 1.6KW | 2.5KW |

| Dimension | 880*760*1800mm | 1050*850*2050mm |

| Weight | 275kg | 380kg |

Features

1. Back sealing,valve piston pump filling meter.

2. Film disinfection, liquid disinfection.

3. The finished packed products are elegant and reliable, hygiene and security.

4. It can automatically finish making-bag, metering, filling, sealing, cutting, counting and printing batch number.

5. The body and the parts touching the material are made of stainless steel.

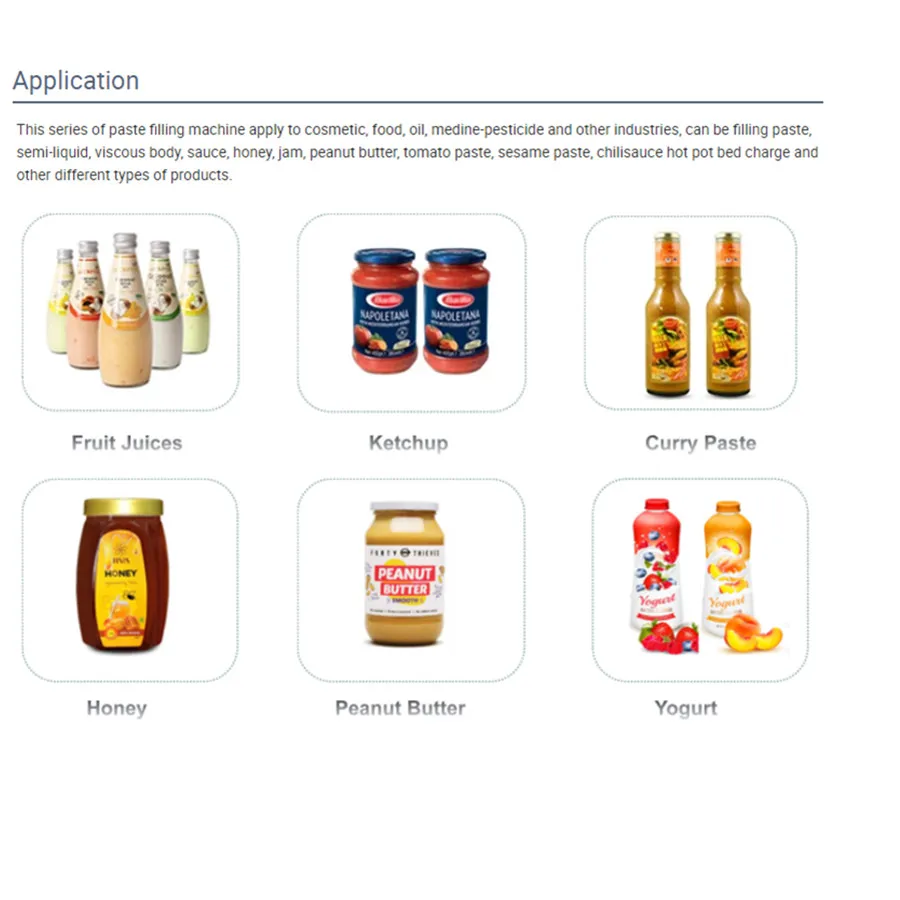

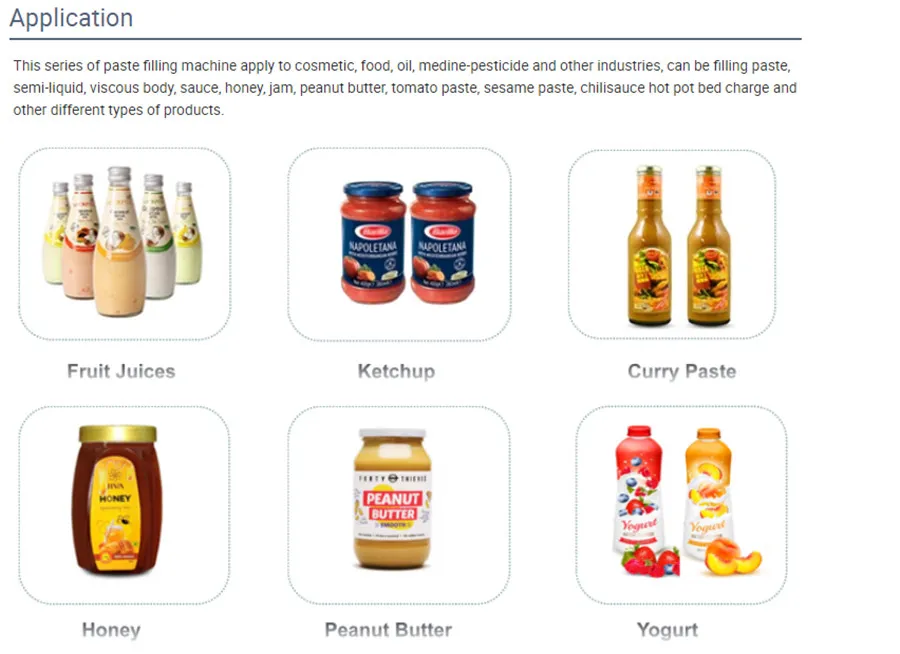

Application

It is applicable for packing the liquid like hairdressing water, hair conditioner, lotion, soy sauce, cough syrup, agricultural chemicals, wine and sauce.

Adopts Computer Controll System completly, it can finish the production's process automatically such as making bags, counting, filling, sealing, cutting, printing batch number, making the rip , and so on. It also adopts the adjustable quantificational plunger pump, and it special uses for something which easy to drawbench or dript as shampoo.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.