Powder Rotary Packing Machine Ultra High Temperature Sterilizer

Product Descriptio:Quick DetailsModelMR8-200CFFunction·Pouch Fill/Sealing Machine·Spout Pouch Packaging MachineCapacity (PPM)30~50bags/min(the speed depends on type of products)Pouch SizeWidth(mm):80~210 Length(mm):100~300Filling Volume10-1500g(Depend on type of products)Fillin......

Send Inquiry

Product Description

Quick Details

Model | MR8-200CF |

|---|---|

| Function | ·Pouch Fill/Sealing Machine ·Spout Pouch Packaging Machine |

| Capacity (PPM) | 30~50bags/min(the speed depends on type of products) |

| Pouch Size | Width(mm):80~210 Length(mm):100~300 |

| Filling Volume | 10-1500g(Depend on type of products) |

| Filling Product | Powder |

| Package Accuracy | Error≤±1 |

| Total power | 2.5KW(220V/380V,3PH,50HZ) |

| Demension | 1460*1560*1480mm(L*W*H) |

| Weight | 1700KGS |

| Compress air requirement | ≥0.8m³/min supply by user |

| Application | Coffee powder; Milk powder; Tapioca powder; Coconut powder, Seasoning |

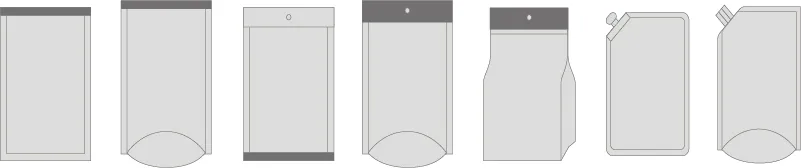

| Pouch type | stand up pouches, zipper bags, paper bags, three/four sides sealed bags... |

| Features | 8 stations; wash down; retortable; easily operate |

| Notes | with auger powder filler/bulk screw feeder/product bulk hopper |

1. Spices and Seasonings Consumption

| As a vegetation product that has an aromatic or pungent to the taste quality, a spice comes from tropical plants in varied forms such as dried seeds or fruit, the barks or roots of certain plants and trees, and berries, seeds, or dried fruits. On the other hand, a seasoning is a mixture of several flavoring components such as sugars, salts and spices. According to the data caluculated by Statista based on the U.S. Census data and Simmons National Consumer Survey (NHCS), spices and seasonings consumption has on a steady rise in the United States from 2011 to 2016 and a forecast thereof until 2020 |

2. Spices and Seasonings Packaged in Four Sides Sealed Bags or Doypack

3. Automatic Rotary Packaging Machine for Spices and Seasonings

Product description

| Features and Characteristics |

| 1. The powder material weighing packaging system consists of a rotary packing machine, auger filler, and screw conveyor |

| 2. A perfect quality ensures a speedy and stable production |

| 3. High-quality accessories ensure the machine durable and stable. Waterproof system makes cleaning easier |

| 4. Color touch screen display, easy to operate. The machine and the other devices make up a packaging system |

| 5. Provide an innovative and practical solution at reasonable costs |

| 6. Low material waste. The machine adopts premade perfect-pattern pouch, with high-quality sealing |

| Application: | Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules, etc |

| Standard Equipment: | 1. date printer 2. PLC control system 3. pouch opening devices 4. vibrator 5. cylinder 6. magnetic valve 7. temperature controller 8. vacuum pump 9. frequency convertor 10. output system |

| Optional Equipment: | material weighing filling machines, work platform, weight checker, material elevator, finished product conveyor, metal detector |

Work Process: Pouch Type:

Pouch Type:

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.