Automatic Packaging Machinery Food Sealing Filling Packing Machine

2023-10-18

"Automatic Packaging Machinery for Food Sealing, Filling, and Packing" refers to a category of equipment used to automate the process of packaging food products by performing tasks such as sealing, filling, and packing. These machines are widely used in the food industry to enhance efficiency, consistency, and productivity in the packaging process. Here's an overview of the key features and functions of such machinery:

Key Features and Functions:

Sealing: These machines are designed to seal packaging materials, such as pouches, bags, or containers, to ensure the contents are securely contained and protected.

Filling: They can accurately dispense and fill food products, including liquids, powders, granules, and solid items, into the packaging.

Packing: The machinery involves the process of placing the filled products into the packaging materials, which could be bags, pouches, cups, trays, or other suitable containers.

Automation: The primary function of these machines is automation, reducing the need for manual labor and increasing the speed and efficiency of the packaging process.

Product Variety: These machines are versatile and can handle a wide range of food products, from dry goods like snacks and grains to liquids like sauces and beverages.

Sealing Mechanisms: Depending on the specific machine, sealing methods can include heat sealing, impulse sealing, ultrasonic sealing, or other techniques.

Filling Accuracy: Automatic packaging machinery can offer precise and consistent filling accuracy, minimizing product waste and ensuring uniform packaging.

Customization: Machines are often adjustable to accommodate various packaging sizes, shapes, and product volumes.

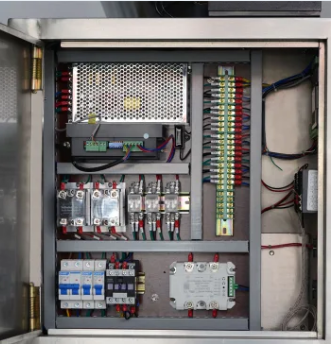

User Interface: Equipped with user-friendly interfaces or control panels that allow operators to set parameters, monitor the packaging process, and make adjustments as needed.

Speed and Throughput: Different models offer varying production speeds, allowing for high throughput and efficiency.

Safety Features: Incorporated safety features ensure the safety of operators and the machinery during operation.

Maintenance: Regular maintenance is essential to keep the machine in optimal working condition and prevent downtime.

Benefits:

Efficiency: Automation reduces manual labor, increases speed, and enhances overall packaging efficiency.

Consistency: Automated processes ensure consistent product placement, filling, and sealing, reducing errors.

Reduced Waste: Precise filling accuracy minimizes product waste, contributing to cost savings.

Product Integrity: Proper sealing and packaging protect food products from contamination and external factors.

Labor Savings: Automated processes decrease the need for manual labor, potentially reducing labor costs.

Considerations:

Product Compatibility: Ensure the machine is suitable for the type of food products you intend to package, including their consistency, size, and properties.

Packaging Materials: Different machines are compatible with different packaging materials, so consider the type of packaging you'll be using.

Maintenance and Support: Choose a reputable manufacturer that provides maintenance support and access to replacement parts.

Initial Investment: The cost of the machine can vary based on features and capabilities, so consider your budget.

When selecting automatic packaging machinery for food sealing, filling, and packing, consulting with experts or manufacturers can help you choose the right machine for your specific packaging needs.