How Can Pipe Benders Transform Industrial Piping Fabrication Today?

2025-10-13

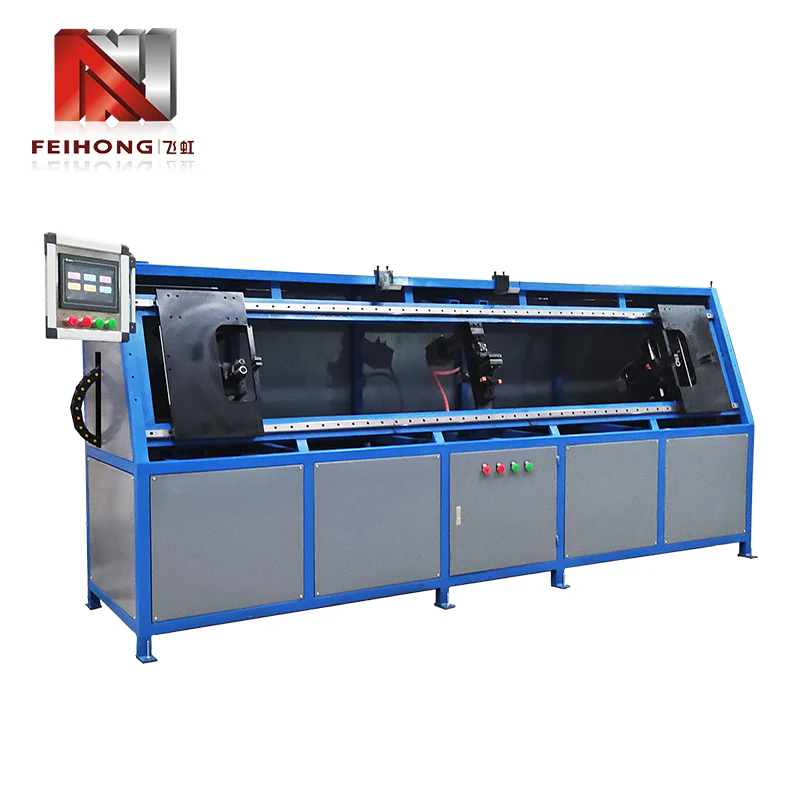

The pipe bending machine, commonly known as a pipe bender, is a precision tool engineered to bend pipes or tubes into desired radii and angles without compromising structural integrity.

What Are Pipe Benders and What Are Their Key Capabilities?

What defines a pipe bender?

A pipe bender is a mechanical (often CNC-controlled) device that applies force to bend a tube or pipe along a curved path without flattening, kinking, or compromising wall thickness. There are several types:

-

Manual pipe benders – operated by human force for small scale or field jobs

-

Hydraulic pipe benders – use hydraulic pressure to bend high-strength or thick-walled pipes

-

Electric / servo-driven CNC pipe benders – use motors, drives, and software control for high precision and automation

-

Rotary draw benders, mandrel benders, roll benders – different bend methods optimized for specific radius requirements

What are the typical performance parameters and specifications?

Below is a representative specification chart reflecting a high-end industrial CNC pipe bender,for reference in comparisons or design:

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Maximum Pipe Outer Diameter (OD) | 10 mm to 219 mm or higher | Determines the largest pipe the machine can bend |

| Wall Thickness Capability | 1 mm to 10 mm (or more) | Impacts structural limits of bending |

| Bending Radius Range | 1.5 × OD to 5 × OD (customizable) | Determines curvature flexibility |

| Bending Angle Range | 0° to 180° | Typical full swing capability |

| Maximum Bending Speed | 0–60°/s or more | Affects throughput for production |

| Control System | CNC / PLC with touch interface | Determines automation, repeatability |

| Drive Mode | Electric servo, hydraulic, or hybrid | Influences power efficiency and maintenance |

| Material Compatibility | Carbon steel, stainless, copper, aluminum | Versatility of the machine |

| Accuracy / Repeatability | ±0.1° or better | Critical for consistent production |

| Tooling / Die System | Replaceable bending dies, mandrels | Flexibility for different diameters |

| Machine Footprint / Weight | Varies by capacity | Affects shop floor layout and foundation needs |

| Power Requirements | 220V/380V / 50Hz or 60Hz | Consideration for installation |

| Safety Features | Emergency stop, protective guards | Worker safety compliance |

That table outlines a robust benchmark. Real-world models can vary; for instance, compact machines might only bend up to 50 mm OD while heavy industrial systems go beyond 300 mm.

What advantages do advanced pipe benders offer over conventional methods?

-

High precision and consistency: CNC control ensures repeated bend accuracy for mass production.

-

Reduced material waste: Precise control over bend geometry preserves wall thickness and avoids over-bending.

-

Flexibility: Quick tooling changes let one machine handle varied diameters and geometries.

-

Productivity boost: Automation and speed help reduce cycle times and labor costs.

-

Complex geometry capability: Multi-axis bending, 3D bends, and compound curves become feasible.

-

Safety and ergonomics: Enclosures, automatic loading/unloading reduce human risk.

Why Are Pipe Benders Crucial in Modern Manufacturing?

Why is bending pipes rather than welding or fabricating in straight segments beneficial?

-

Structural integrity: A bent continuous pipe has fewer joints, reducing leak points and stress concentration.

-

Aesthetic and functional design: Smooth curves are often preferred in architectural, HVAC, and automotive systems.

-

Flow efficiency: Curved transitions reduce turbulence versus abrupt elbows or welded joints.

-

Labor and time savings: Fewer joints or connectors means fewer welds, less assembly time.

-

Space optimization: Complex routing in tight spaces often demands precision bends rather than straight segments with joints.

Why must manufacturers invest in advanced pipe bending technology now?

-

Rising demand for customization: Industries require bespoke pipe runs for complex systems in renewable energy, robotics, and aerospace.

-

Cost pressures and automation trends: Labor shortages push fabrication toward machine-driven processes.

-

Material challenges: Modern alloys (e.g., high strength steels, duplex stainless) require sophisticated bending to avoid cracks or workhardening.

-

Quality and regulatory standards: Infrastructure, oil & gas, and transport sectors demand tight tolerances and certification compliance.

-

Global competition: Manufacturers that integrate high-performance bending stand to win contracts by offering faster lead times and superior quality.

Why consider brands with strong engineering support and aftersales?

-

Tooling design support: Correct dies and mandrels are critical, and inexperienced tooling can damage expensive machines.

-

Software and control updates: Top manufacturers deliver continuous improvements.

-

Spare parts and service network: Minimizing downtime is essential in production setups.

-

Training and troubleshooting: Local support ensures smooth adoption and operation.

How Do Pipe Benders Work? What to Watch For in Selection and Operation?

How does a pipe bending machine perform the bending process?

-

Clamping / Gripping – The pipe is held firmly to prevent slipping or deformation.

-

Bend driving – A bending die or arm forces the pipe around a radius; in mandrel bending, internal support prevents collapse.

-

Counterbend / Pressure die – A die on the opposite side prevents wrinkling or distortion.

-

Mandrel insertion (if used) – For tight bends in thin walls, a mandrel stabilizes the inner radius.

-

Unclamp and release – After bending, the pipe is released and either removed or advanced for the next bend.

-

Back bender or secondary axes – For complex bends, additional axes or back-benders may adjust torsion or offset angles.

How to select the right pipe bender for your application?

-

Material and wall thickness profile: Heavier walls require stronger machines or hydraulic models.

-

Required minimum bend radius: Choose whether you need tight radii or gentle curves.

-

Production volume / cycle time: High throughput demands servo or hybrid systems.

-

Number of axes: Multi-axis bending (e.g., 3D) demands more complex machines.

-

Tooling flexibility and availability: Ease of changing dies and mandrels is critical for mixed production.

-

Software capability: Support for offline programming, simulation, and integration is advantageous.

-

Service and spare support: Particularly important for industrial operations 24/7.

How to operate and maintain a pipe bending machine for longevity and performance?

-

Ensure lubrication of bearings, slides, and moving parts regularly.

-

Conduct calibration checks to maintain accuracy over extended production.

-

Inspect tooling (dies, mandrels) for wear and replace in timely fashion.

-

Follow manufacturer’s schedule for hydraulic oil replacement or filter changes.

-

Train operators in safe loading, unloading, and error recovery procedures.

-

Use sensors and fault detection systems to catch anomalies before damage occurs.

-

Monitor bending load and adjust parameters to avoid overstrain or exceeding design limits.

What Trends Are Shaping the Future of Pipe Bending Technology?

What innovations are emerging in pipe bending?

-

Intelligent / IIoT integration: Real-time monitoring of bending loads, predictive maintenance, and remote diagnostics.

-

Robotic bending cells: Integration with robots for automated loading/unloading and bend sequencing.

-

Adaptive bending algorithms: Software that compensates automatically for material springback and variation.

-

Lightweight and composite pipe bending: Machines developed to handle nonmetallic materials (e.g. carbon fiber reinforced tubing).

-

Modular and compact designs: Space-saving solutions for small factories or regional deployment.

-

Energy efficiency: Recovery systems or hybrid drives to reduce power consumption.

-

Augmented reality / digital twin support: Virtual simulation for programming and operator guidance.

What challenges lie ahead?

-

Handling advanced alloys: New materials with high yield strength require more control and precision.

-

Upfront cost vs ROI justification: High initial investment must be justified by throughput and quality gains.

-

Workforce skills gap: Recruiting and training skilled CNC operators is a persistent issue.

-

Integration across workflows: Ensuring smooth data flow between CAD/CAM, bending control, inspection, and ERP systems.

-

Standardization of tooling interfaces: A fragmented tooling ecosystem can hinder interchangeability and efficiency.

Common Questions on Pipe Benders (FAQs)

Q: What is the minimum bend radius achievable without wrinkling or collapse?

A: The minimum bend radius depends on pipe diameter, wall thickness, material ductility, and whether a mandrel is used; with mandrel support, many machines achieve 1.5× OD or even tighter bends, whereas unstabilized bends might be limited to 2–3× OD or more depending on materials and wall.

Q: How is springback accounted for in precise bending operations?

A: Advanced bending software includes compensation for material springback by overshooting the bend slightly, based on empirical or stored material curves; high-end machines may automatically adjust the final angle in a closed-loop control to reach the target precisely.

Combining deep understanding of what pipe benders are, why they’re indispensable, and how they operate and evolve lays a foundation for making informed investment and operational decisions. By addressing key performance parameters, emerging trends, and answering common technical questions, prospective buyers or users gain clarity in defining requirements and comparing machines. In the shifting landscape of digital manufacturing and automation, selecting a pipe bending solution backed by robust support and technical capability is critical.

Feihong is a specialized provider known for delivering precise, customizable pipe bending machines tailored to demanding industrial applications. With decades of expertise and responsive service, Feihong offers solutions to meet your fabrication goals. For further consultation, specifications, or to discuss your pipeline project needs, contact us today.