How Do I Choose the Right Tags For My Packaging And Printing Needs?

2025-11-05

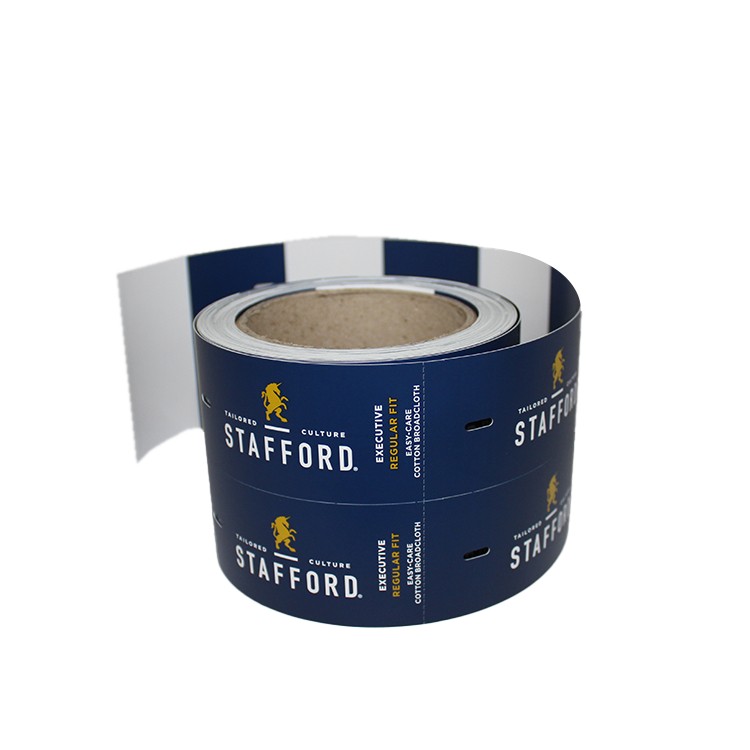

When I first audited our packaging line, I realised how often Tags were treated like an afterthought. That changed after I worked with Guang Dong-Hong Kong (GZ) Smart Printing, whose engineers kept reminding me that a tag is a physical component with paper width limits, fold types, coating choices, and print tolerances that affect uptime and cost. This guide answers the questions buyers ask me most and shares the checklist I now use before every order.

What Problems Do Physical Tags Actually Solve On The Line?

-

I reduce picking errors with scannable layouts that fit my scanners’ depth of field

-

I speed up kitting by matching fold type to the handler’s motion pattern

-

I keep thermal printers running by buying paper that matches the machine’s supported width and core size

-

I cut label waste by choosing the right perforation and tear strength

-

I pass audits by locking down color targets and traceability fields from day one

Important reminder

Tags paper has single fold, double fold and multiple specifications. Please pay attention to the paper width of the machine when purchasing. It is a physical label, not the internet “tag”.

Which Tag Fold Should I Use For My Products?

| Use Case | Single Fold Tag | Double Fold Tag | Multi Fold Tag |

|---|---|---|---|

| Typical product size | Small items and retail pieces | Medium cartons and bundles | Long BOMs and export packs |

| Print area | Front and back only | Four printable panels | Six or more panels |

| Best for handling | Fast tear and apply | Extra space for compliance | Dense data and multilingual content |

| Perforation need | Optional | Recommended | Strongly recommended |

| Unit cost | Lowest | Medium | Highest |

| Risk if misused | Not enough space for data | Slight bulk on tight shelves | Jam risk on narrow feeds |

I use single fold when the data is simple. I step up to double fold for extra fields and barcodes. I pick multi fold only when the product needs multilingual instructions or long traceability strings.

How Do I Match Paper Width To My Printers Without Trial And Error?

-

I confirm the printer’s maximum printable width and supported media width in millimeters

-

I check core size, outer roll diameter, and sensor type for gap vs black mark

-

I match perforation spacing to my cutter’s pitch

-

I run a five-minute dry feed test with unprinted stock before a long run

-

I log the approved spec so reorders stay consistent

Quick checks that save me from jams

-

Does the machine support the actual paper width I am buying

-

Is the fold height compatible with the printhead path

-

Do my applicators tolerate the added thickness of multi fold stock

What Should I Print On My Tags To Reduce Returns?

-

Human-readable SKU and short product name

-

Lot and date codes placed away from folds and perforations

-

Barcode or QR that meets scanner contrast requirements

-

Country of origin, material warnings, and recycling marks

-

Service URL or QR that lands on a mobile friendly page

I place the most critical data on the first visible panel so workers see it the moment they pick up the tag.

How Do I Choose Paper, Coatings, And Adhesives For Real Conditions?

-

I choose paper weight that matches handling stress

-

I use matte coatings for scanner readability and glossy only for retail shine

-

I request scratch and rub tests for high-friction lines

-

I spec moisture resistance when the warehouse is humid

-

I pick adhesives based on surface energy and removal needs

I do one small trial per environment. A short test in the hottest aisle has saved me more money than any discount.

How Do I Keep Colors Accurate Across Reorders?

-

I define Pantone or Lab* targets and delta-E tolerance

-

I require printed swatches on the exact stock

-

I approve one master proof and keep it on file

-

I ask for a press report with density readings

My rule is to lock the brand color on day one and never let it drift.

How Do I Cut Waste And Speed Up Application?

-

I set perforation lines where workers actually tear

-

I pick fold sizes that match hand spans and bins

-

I group items by identical tag size to reduce changeovers

-

I print batch codes so returns can be traced to a lot, not a whole range

A ten-minute line study often removes one fold and one wasted step.

What Specifications Do I Share With My Printer To Get A Clean Quote?

| Spec I Provide | Why It Matters |

|---|---|

| Media width in mm | Ensures the stock fits my printers and applicators |

| Fold type and finished size | Controls layout, panel count, and cost |

| Core size and roll OD | Prevents loading issues and mid-run stoppage |

| Perforation position and strength | Balances tear ease and tag integrity |

| Paper weight and coating | Matches durability and scanner needs |

| Barcode type and size | Ensures scan rates at working distance |

| Color targets and tolerance | Keeps brand consistent across reorders |

| Quantity by SKU and delivery waves | Optimises pricing and inventory |

When I include these details, I get fewer surprises and cleaner lead times.

Where Do Buyers Most Often Go Wrong And How Do I Avoid It?

-

Ordering internet sized “tags” that are not physical Tags I need

-

Ignoring the machine’s paper width and jamming the printer

-

Cramming too much data onto a single fold

-

Using glossy stock under harsh lighting and hurting scan rates

-

Skipping a dry feed test and discovering curl at hour four

I avoid all five by standardising a one page spec and a two hour pilot run.

Why Do I Prefer Working With A Specialist Supplier Instead Of A General Printer?

I value fast DFM feedback, stocked paper widths, and consistent QC. Teams like Guang Dong-Hong Kong (GZ) Smart Printing help me optimise fold type, perforation strength, and width before I spend a cent on a long run. That is how I keep uptime high and costs predictable.

What Is My Final Checklist Before I Place The Order?

-

Confirm physical tag type and fold count

-

Verify machine paper width, core size, and sensor marks

-

Lock barcode size, quiet zones, and print direction

-

Approve proof on the exact stock and coating

-

Run the dry feed test and sign off on waste limits

Once these are done, I place the PO with confidence.

Would You Like Help Turning This Into A Ready To Print Spec?

If you want me to review your current tag files, I can map them to the folding method and width compatible with your printer, providing a concise, print-ready specification document within one working cycle. Please advise the target printer model and provide photographs of your current labels, and I shall recommend the solution presenting the lowest risk.

Ready to optimise your Tags

Have questions or need a fast quote. Please contact us and leave your inquiry. I will review your requirements, recommend the best fold and paper width for your machines, and help you go from draft to delivery without surprises.