How Do You Choose the Right Drum Pulleys for Your Conveyor Setup?

2025-07-09

What should you consider first when selecting drum pulleys

Before choosing any component, it’s essential to understand the operating conditions of your conveyor. The size, speed, belt type, and material load will influence what kind of drum pulleys you need. Starting with a clear understanding of your system requirements ensures better performance and longer service life.

How do material and construction affect drum pulley durability

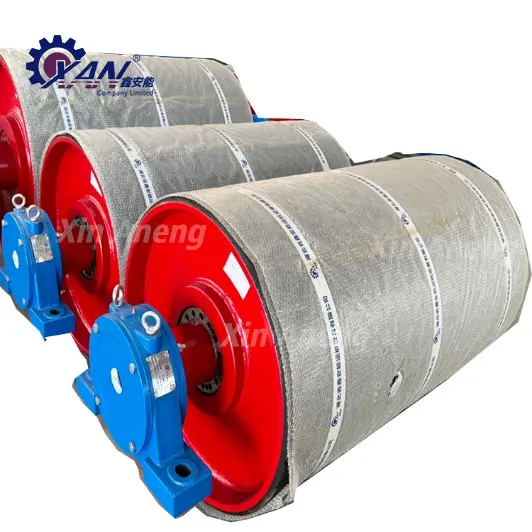

Drum pulleys made from heavy-duty steel or stainless steel provide high strength and corrosion resistance. In dusty, wet, or chemical-heavy environments, coated or lagged drum pulleys reduce wear and prevent slippage. The construction quality directly impacts how well your pulleys withstand harsh conditions.

Why is proper sizing important for drum pulleys

Incorrect sizing leads to belt misalignment and premature wear. The diameter, shaft size, and face width of your drum pulleys must match your conveyor’s design and load requirements. A properly sized drum pulley supports smoother belt movement and minimizes stress on the system.

Can drum pulleys improve energy efficiency

Yes, they can. Well-balanced drum pulleys reduce vibration and friction, which in turn decreases energy loss and operational noise. Choosing energy-efficient components helps lower power consumption and improves overall system sustainability.

How do maintenance and replacement impact long-term cost

Regular inspection of drum pulleys ensures early detection of wear or imbalance. When maintenance is delayed, failures can damage the entire conveyor belt. Selecting durable, easy-to-service drum pulleys reduces unplanned downtime and long-term repair costs.

Conclusion

How do you choose the right drum pulleys? By evaluating load capacity, material strength, size, and operating environment. With the right selection, your drum pulleys will not only enhance performance but also extend the life of your conveyor system.