What Makes Cosmetic Packaging Feel Premium Yet Practical for Modern Beauty Brands?

2025-12-25

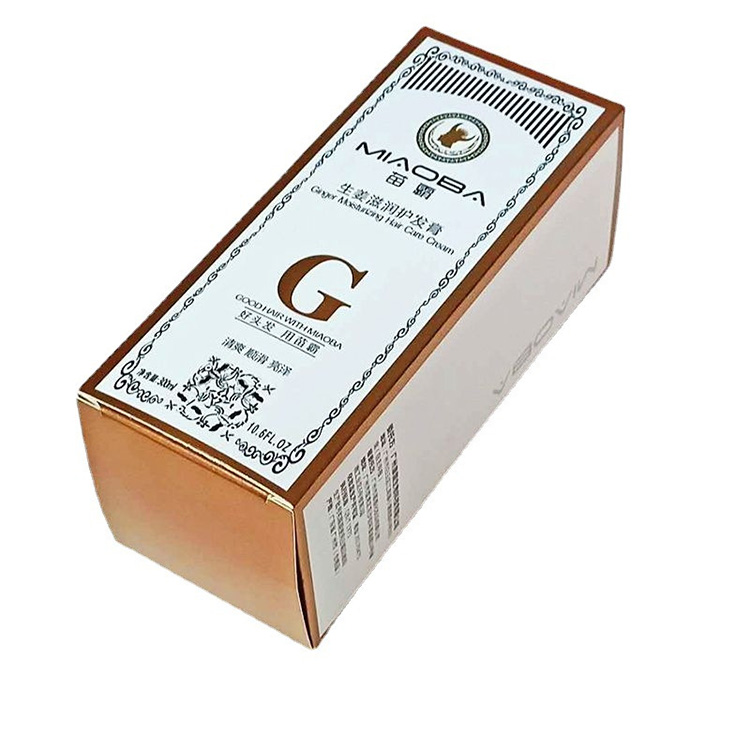

If you’ve been comparing suppliers, you’ve probably noticed how easy it is for Cosmetic Packaging to look good in a catalog—but fail in real life: pumps that clog, caps that crack in transit, labels that peel in a humid bathroom, or colors that don’t match your brand once they’re actually produced. I’ve been on the “why is this so complicated” side of sourcing too, which is why I started working with partners like Dicai—not because I needed more options, but because I needed fewer surprises and more control over the outcome.

In this article, I’ll break down how I evaluate Cosmetic Packaging based on what buyers actually care about: shelf impact, formula compatibility, shipping durability, compliance needs, and cost predictability. The goal is simple—help you choose packaging that sells, protects your product, and doesn’t create a customer service headache later.

Why does cosmetic packaging fail even when it looks perfect on screen?

Most packaging problems aren’t “design” problems—they’re “use-case” problems. A render can’t tell you how a cap threads after 300 openings, how a pump behaves with a high-viscosity serum, or whether a metallized finish will scuff in a master carton.

- Leakage and mess from poor sealing, wrong liner selection, or mismatched neck finish

- Dispensing issues when pumps aren’t spec’d for viscosity, particle content, or airless requirements

- Decoration wear from friction, alcohol-based sanitizers, or heat/humidity during logistics

- Color inconsistency across batches or between components (cap vs bottle vs actuator)

- Unplanned cost spikes from tooling changes, rework, or late-stage artwork adjustments

When I source Cosmetic Packaging, I’m not just buying a container—I’m buying repeatability. That means clear specs, realistic testing, and a supplier who thinks like a manufacturer, not a showroom.

How do I choose the right material without overpaying for “premium”?

“Premium” isn’t a material—it’s a combination of weight, finish, stability, and how it performs in-hand. I pick materials based on what the product needs and what the brand promise is.

| Material | What I like about it | Watch-outs | Best fit |

|---|---|---|---|

| Glass | High-end feel, excellent barrier, strong for active formulas | Heavier shipping cost, breakage risk, needs protective packing | Serums, fragrances, luxury skincare |

| PET | Lightweight, good clarity, cost-effective, widely recyclable | Barrier can vary, may need additive or special design for certain actives | Toners, cleansers, daily skincare |

| Acrylic | Beautiful clarity and premium appearance | Recycling complexity and scratch sensitivity depending on finish | Prestige creams, display-focused lines |

| Aluminum | Great light barrier, modern look, strong sustainability story | Needs inner coating for some formulas, dents if not designed well | Balms, mists, hair care |

| Paper-based packaging | Excellent for branding, unboxing, and shelf storytelling | Moisture sensitivity, needs smart structure and surface treatment | Outer boxes, gift sets, sustainable presentation |

With Cosmetic Packaging, I usually start with a “must-have” list (barrier, dispensing, durability) and only then decide where to spend on finish. That keeps budgets honest and results consistent.

What details actually make packaging feel high-end in a customer’s hand?

Customers judge your brand in seconds. The feel of the closure, the sound of the click, the smoothness of the pump—those little cues create trust. When I review samples, I focus on tactile and functional signals that users notice even if they can’t name them.

- Weight and balance so the product feels stable and intentional

- Closure precision with smooth threading and no wobble

- Dispensing control that avoids splatter, clogging, or inconsistent output

- Surface finish that resists fingerprints and scuffing during shipping

- Decoration accuracy with clean registration and demonstrated rub resistance

When Dicai helps refine Cosmetic Packaging, the most valuable part is often the “small” engineering: improving fit, tightening tolerances, recommending a different pump core, or suggesting a finish that holds up better in transit.

How do I reduce leakage and returns without redesigning everything?

If returns are creeping up, I don’t jump straight to a full packaging overhaul. I diagnose the failure point first, then fix what’s actually causing it.

- Seal upgrade by adjusting liners, adding inner plugs, or improving closure fit

- Neck finish matching to ensure caps and pumps mate correctly

- Airless solutions for formulas that oxidize or separate easily

- Shipping tests including drop, vibration, and temperature cycling based on your lanes

- Torque guidance so closures aren’t under- or over-tightened in filling

Most brands don’t need “more expensive” Cosmetic Packaging. They need packaging that’s better matched to formula behavior, filling conditions, and real logistics.

Which customization options help branding the most without slowing down lead times?

Customization is where brands win—until it turns into delays, rework, and inconsistent output. I like to prioritize customizations that are high-impact and controllable.

- Color-matched components that align with brand codes across caps, bottles, and pumps

- Surface finishes like matte, soft-touch, or frost that elevate perception instantly

- Decoration methods such as silk screen, hot stamping, or labeling chosen based on durability needs

- Structural tweaks like better ergonomics, improved base stability, or upgraded actuators

For Cosmetic Packaging, the best customization is the kind that scales—meaning it can be repeated across production runs without constant re-approval cycles.

What should I ask a supplier to avoid quality surprises after I place the order?

I keep my supplier questions practical and production-focused. If a supplier can answer these clearly, it usually means they have systems, not guesswork.

- What are the key tolerances for this component set and how are they measured?

- How do you manage color consistency between batches and between parts?

- What tests do you recommend for my formula type and shipping lanes?

- How do you control decoration adhesion and rub resistance?

- What packaging protection is used for transit to prevent scuffs and breakage?

That’s how I keep Cosmetic Packaging predictable—because “pretty samples” don’t protect you from production variability.

How can cosmetic packaging support sustainability without hurting performance?

Sustainability is no longer a bonus—it’s a buying factor. But sustainable choices still need to work: closures must seal, pumps must dispense, and materials must protect the formula.

- Lightweighting to reduce material usage and shipping emissions

- Recyclable material choices based on your target markets’ infrastructure

- Refill-friendly formats that keep the premium shell and replace the inner

- Right-sizing outer packaging to reduce waste without increasing damage rates

My rule is simple: sustainable Cosmetic Packaging should still pass real-world handling and transit. If it can’t, it becomes waste anyway—just later in the chain.

Ready to upgrade your packaging without trial-and-error headaches?

If you want Cosmetic Packaging that looks on-brand, performs reliably, and stays consistent from sampling to mass production, I’d rather help you do it once and do it right. Share your product type, target market, preferred material, and the vibe you’re aiming for, and I’ll map out practical options with clear trade-offs. When you’re ready, contact us to request samples or a quotation—let’s turn your packaging into something customers recognize instantly and trust every time they use it.