Why Are Drum Pulleys a Key Component in Conveyor Systems?

2025-07-09

What are drum pulleys and how do they function in a conveyor

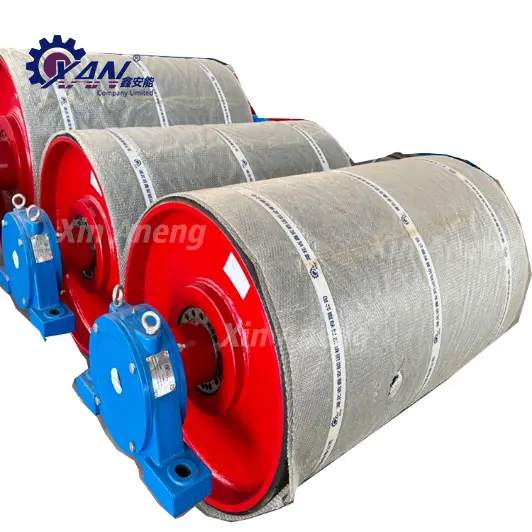

Drum pulleys are cylindrical components that provide the driving force or tension support for conveyor belts. Typically mounted at either end of a conveyor frame, they rotate to move the belt and transport materials efficiently. Whether they serve as drive pulleys or tail pulleys, drum pulleys are fundamental in ensuring continuous and smooth material handling.

Why do drum pulleys matter for operational efficiency

Conveyor systems must run smoothly and with minimal downtime. Drum pulleys directly impact performance by maintaining proper belt tension, alignment, and grip. A worn or misaligned drum pulley can lead to belt slippage, damage, or stoppage—making maintenance and quality essential.

How do different drum pulley designs affect performance

Drum pulleys come in various diameters, face widths, and surface coatings such as lagging or rubberized covers. Each design fits specific loads, belt widths, and environmental conditions. Choosing the right type of drum pulley ensures better friction, longer lifespan, and improved traction.

Can drum pulleys be customized for special applications

Absolutely. Custom drum pulleys can be made from stainless steel, carbon steel, or even aluminum. They can include features like crowned faces, vulcanized lagging, and bearing housings. Whether you're working in mining, food processing, or logistics, the right drum pulley can be tailored to meet industry-specific demands.

Why is it important to invest in high-quality drum pulleys

Low-quality drum pulleys wear faster and may cause misalignment, belt damage, or increased energy consumption. Investing in well-machined, balanced drum pulleys ensures stability, reduces long-term costs, and improves conveyor efficiency across all sectors.

Conclusion

So why are drum pulleys such a vital part of your conveyor system? Because they provide the torque, support, and alignment needed for continuous operation. Without durable and precise drum pulleys, your entire material handling process could grind to a halt.