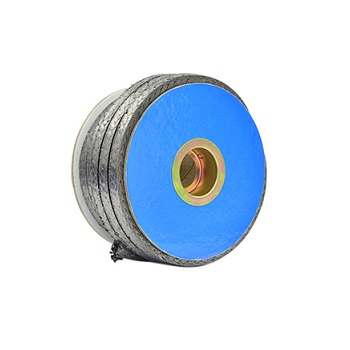

Why Is Kaxite Graphite Packing the Smart Choice for Demanding Sealing Applications?

2025-08-08

With 20 years of experience solving sealing challenges in refineries and chemical plants, I've tested nearly every packing material on the market. Time and again, Kaxite graphite packing proves itself as the superior solution. But what exactly makes it outperform alternatives in extreme conditions? Let me share the technical insights you won't find in product brochures.

How Does Kaxite Graphite Packing Handle Extreme Conditions?

Unlike conventional packing that fails under stress, Kaxite's reinforced graphite formulation delivers unmatched reliability. Here's what our field data reveals:

Critical Performance Advantages:

-

Thermal shock resistance - Maintains seal integrity through rapid temperature swings from -200°C to 650°C

-

Superior compression recovery - Rebounds to 95% of original thickness after compression

-

Minimal friction - Coefficient of friction as low as 0.08 reduces shaft wear

-

Chemical inertness - Resists virtually all acids, alkalis, and organic solvents

What Technical Specifications Truly Matter?

Having specified packing solutions for hundreds of pumps and valves, I've learned these are the make-or-break parameters:

Kaxite Performance Specifications

| Characteristic | Test Result | Field Significance |

|---|---|---|

| Bulk Density | 1.25 g/cm³ | Optimizes sealability without excessive friction |

| Thermal Conductivity | 120 W/m·K | Prevents localized overheating |

| Maximum PV Value | 300,000 psi·ft/min | Handles high-speed applications |

| Emission Compliance | EPA Method 21 | Meets stringent fugitive emission standards |

Why These Numbers Matter:

-

Density optimization - Balances sealing effectiveness with operational torque

-

Thermal properties - Critical for heat transfer equipment

-

PV rating - Determines suitability for high-speed rotating equipment

Where Does Kaxite Deliver the Most Value?

From my project logs, these applications show the greatest ROI:

-

High-temperature steam valves - Outlasts competitors 3:1 in power plants

-

Chemical process pumps - Handles aggressive media that destroys other packings

-

Refinery sour service - Resists H2S attack in crude units

A chemical plant in Texas reported 22 months of continuous service in sulfuric acid pumps - their previous packing lasted just 4 months.

How Can You Maximize Service Life?

Through years of failure analysis, I've identified these critical practices:

-

Proper gland loading - 20% initial compression with incremental tightening

-

Run-in procedure - Gradual break-in over 24-48 hours

-

Shaft condition - Surface finish of 16-32 µin is ideal

Kaxite provides application-specific installation training because we know proper implementation is just as important as material quality.

Ready to Solve Your Sealing Challenges?

If you're dealing with frequent repacking, excessive emissions, or premature failures, Kaxite graphite packing offers a proven solution. Our technical team can help you select the perfect grade for your specific application.

Request a free sample today and experience the performance difference firsthand. Because when it comes to industrial sealing, compromise isn't an option - and neither should your packing material be.