Home > Products > Bag Making Machine > Fully Automatically Plastic Bag on Roll with Core or Coreless Disposable Table Cover Making Machine Manufacturers

Fully Automatically Plastic Bag on Roll with Core or Coreless Disposable Table Cover Making Machine Manufacturers

HSYW-700VAutomatic Bag-On-Roll Making MachineWith Core & CorelessApplicationThis machine is heat sealing and perforation for bag rewinding, which are suit for printing and non-printing bag making. The material of bag is HDPE,LDPE and recycle materials.HSYW-1000V is designed for bag-on-roll bags ......

Send Inquiry

Product Description

| HSYW-700V Automatic Bag-On-Roll Making Machine With Core & Coreless |

| Application |

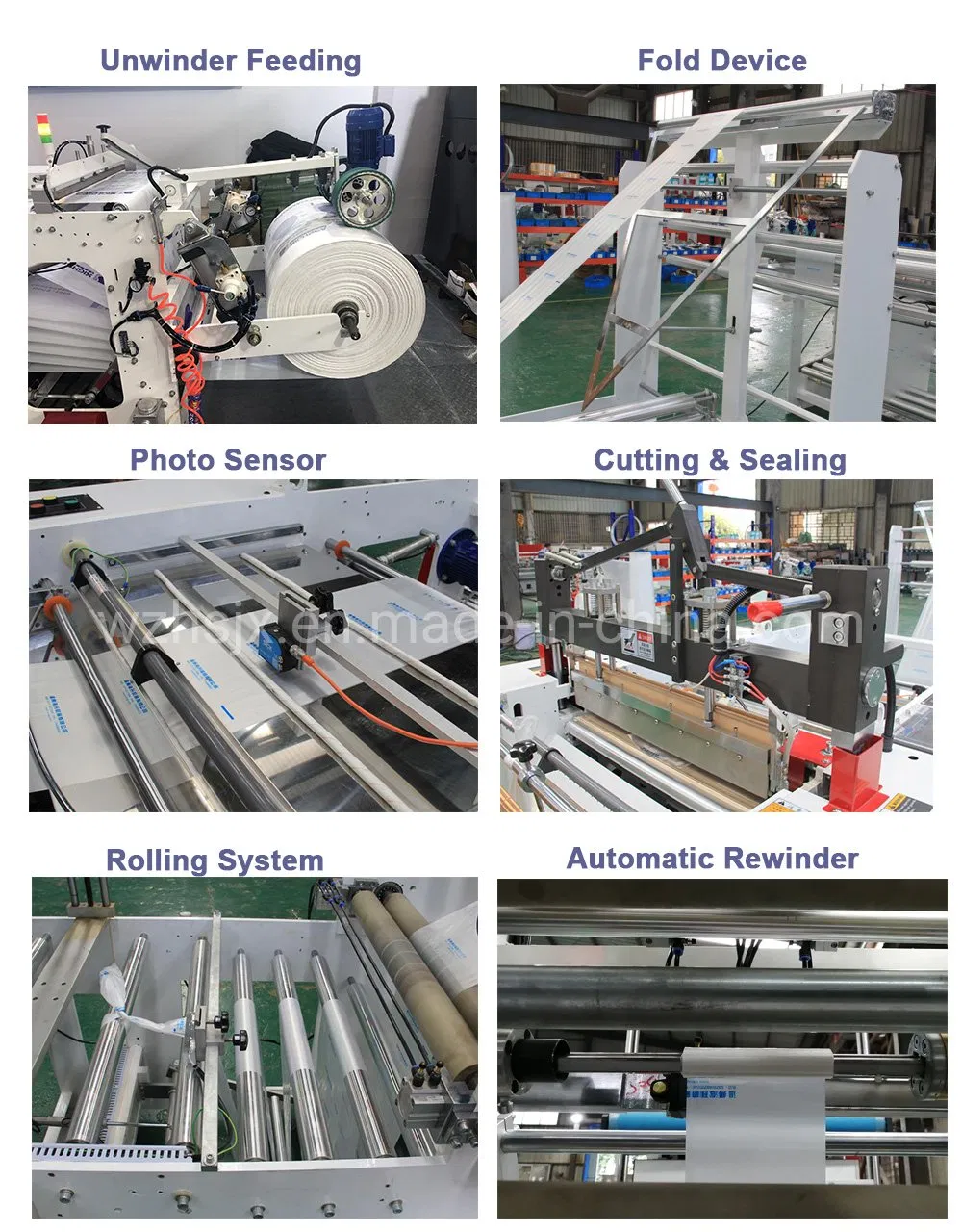

| This machine is heat sealing and perforation for bag rewinding, which are suit for printing and non-printing bag making. The material of bag is HDPE,LDPE and recycle materials. HSYW-1000V is designed for bag-on-roll bags with core and without core productions.The machine have 2 options:

It's automatic film-break and core-change functions help bag suppliers to improve bag making capacity and to reduce energy and man power at the most extent. Its servo motor control system makes producing more stable. It is the best choice for making bottom sealing printed bags and blank bags. |

| TECHNICAL PARAMETER | |

| Production Line | 1 Line |

| Unwinder Film Width | 600mm-1100mm |

| Bag on roll Width | 400 mm - 600 mm |

| Bag Length | 150-1500 mm |

| Film thickness | 7-35 micron per layer |

| Production Speed | 60-80 m/min x 1line |

| Core Diameter(Min.) | 25-60 mm |

| Rewinder Diameter | 150mm (Max.) |

| Film Unwind Diameter | Φ900mm |

| Total Power | 11KW |

| Air consumption | 6HP |

| Machine Weight | 2800KG |

| Machine Dimension | L7000*W2000*H1900mm |

| Samples of Plastic Bag |

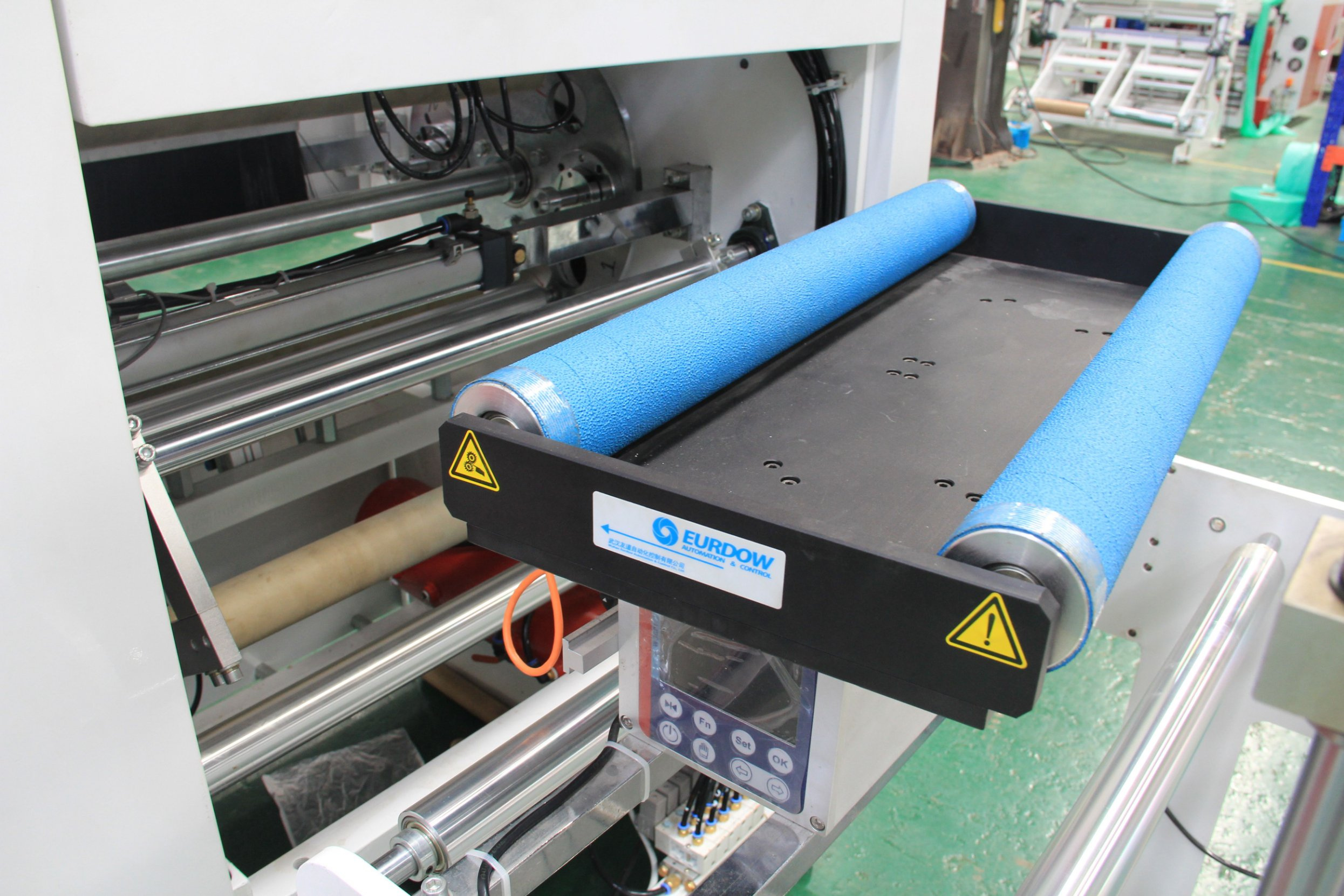

| Feature and structure |

1. Main control panel adopt touch screen Delta from Taiwan, high definition 2. The drive system of whole machine adopts PLC Microcomputer control (Single Chip control system ) on punch machine which integrate control of bag making part and punching part. 3. Set all function with one touch screen, simple and easy operation. 4. Machine will automatically stopped if film jammed which is detected by sensor 5. Independent winder part, high efficient unwind control; max diameter of single unwinding is 800mm; unwinding roller is choked by air shaft, 6. Automatic fold function and put on conveyor unit by unit. 7. Automatic stacks the bag and collects. 8. When the bags stack at the Set numerical, mechanical hands will automatically grab bags and machine will not stop.) on punch machine which integrate control of bag making part and punching part. |

| SPECIFICS |

| The condition of machine operating |

| A. illumination no exceed 3000LX B. altitude no exceed 1000m C. The temperature of stuff around the machine should be no higher than +40ºC and no lower than -20ºC. D. The relative humidity of air no exceeds 85%. E. The place should no have conductive dust. F. Circumstance of no blast danger and fire. |

| Company Brief Introduction |

| Wenzhou High Sea Machinery CO.,LTD is founded in 1996 (Formerly known as Jinfeng plastic packaging machinery factory). For more than 22 years, we focus on researching, developing, manufacturing and marketing on plastic bag making machine. Our products include : 1.Plastic T-shirt Bag Making Machine 2.Vegetable Bag on Roll Making Machine With Core 3.Garbage Bag Making Machine Coreless 4.Draw Tape Garbage Bag on Roll Making Machine 5.Soft Loop Handle Bag Making Machine There are more than 54 countries and regions cooperating with us, such as south Korea, Turkey, Malaysia, Russia,Iran, Ethiopia, Chile, Saudi Arabia, Peru, Algeria,Vietnam,etc. |

| Work Shop |

| Cooperation Brand |

| Exhibition |

| Other Products |

| FAQ |

| 1.Q: How long will your engineer reach our factory? A: Within 7-15 days after machine arrival your factory. |

| 2. Q: How many days will you finish installing ? A: We will finish installation and training within 3-7 days. |

| 3. Q: What should we charge for your engineer? A: You should charge for the cost of our engineer's visa , round trip tickets, accommandation, and also their salary 100USD one day per person. |

| 4. Q: How long is your machine's warranty period? A: All our machine have one year guarantee, starting from finished installation. |

| 5. Q: How could we do after one year warranty period? A: We also can do service for you, but you need pay salary for my technician 100USD/day. |

| 6. Q: How could we do if the parts broken within warranty? A:We would express the free replacement parts during the warranty date. |

| 7. Q: Does your engineer understand English? A:Our engineer understand a little English. All of our engineers have more than five years machine installation experience. |

| 8. Q: How many worker do we need running those machines? A: Usually need one person to opertate the machine. |

| 9. Q: How do we solve the machine problem after your engineer leaving? A: Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description. |

| 10. Q: How can I visit your company? A : It takes 50 minutes by car from Wenzhou Air Port to our factory . And it takes only 10 minutes by car from Ruian train station to High Sea factory . |

| Contact Person | |

| Name: Kiki Mob: 0086-18066385868 E -mail : sale5 @ haisheng .cc Youtube: High Sea Jan | Web: wzhsjx.en.made-in-china.com Web:wzhsjx.en.made-in-china.com TEL: 0577-63773388 FAX:0577-63773366 |

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.